ORIGIN

1955

Joan Iglesias starts his activity in the textile industry, dedicated to the manufacturing of fabrics with a focus on interlining (“Sidos”, “crinyolines” and “torcrins”).

The components of these fabrics were manufactured from natural fibres: Goat hair, horsehair and pig hair. All of these spun and woven with cotton.

1968

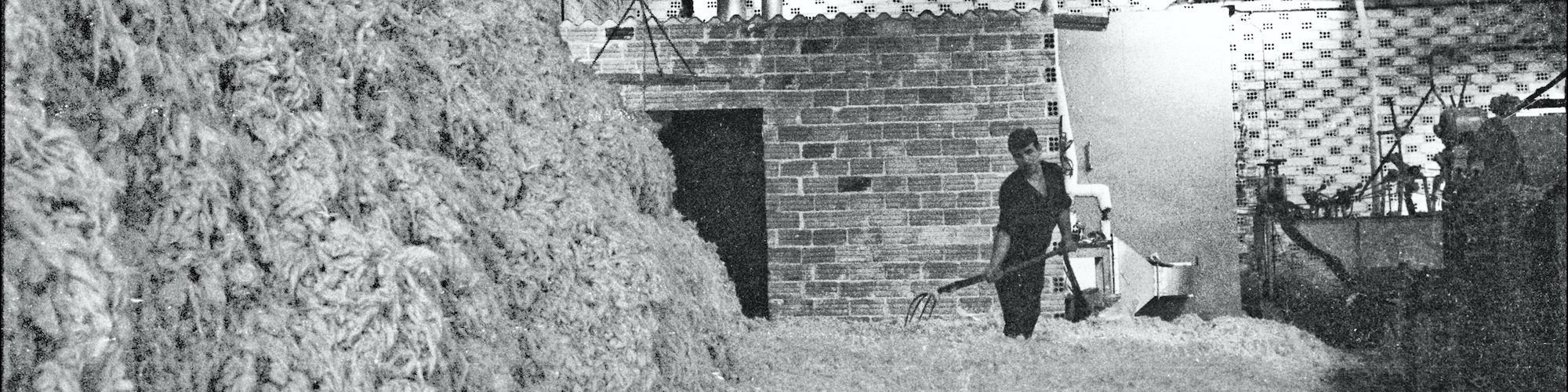

Mr. Joan Iglesias starts a new business whose purpose is to take advantage of the wool generated as a by-product of leather at the tanneries of Vallès Oriental and Osona.

- Activity: Reclamation of wool and tannery by-products.

- Raw materials: Heads, tails and scraps of sheep leather.

- Production destination: Local market (Sabadell and Terrassa).

- End product: Wool flock.

1979

Recuperación de Materiales Textiles S.A. is established, incorporating the wool reclamation line started by Joan Iglesias.

1981

Recuperación de Materiales Textiles S.A. creates the Catexlan S.A. company, which starts handling all activities involving water consumption.

Catexlan S.A. activities:

- Wool reclamation from leather.

- Wool scouring.

- Wool carbonization.

- Wool bleaching.

1992

In 1992, due to the textile industry crisis and the impossibility to adapt to new environmental regulations, Catexlan S.A. shuts down its business.

Recuperación de Materiales Textiles S.A. continues its activity at the Santa Eulalia de Ronçana facility, where a new dry bleaching and standardization process is developed. Wool scouring is outsourced to facilities which comply with the new environmental regulations.

2004

Recuperación de Materiales Textiles S.A. moves to new facilities at the Can Magre Industrial Park, where we nowadays keep perfecting our working systems.

ENTREPRISE

Our area of action involves the purchase of wool, classification, scouring, standardization of the different lots of wool and their final treatments.

Our treatment systems are the product of many years of experience, our main goal being achieving the least possible environmental impact.

Treatments we perform:

- Bleaching

- Mothproofing

- Fungicide

- Fire retardant

Most wools and treatments can be accompanied by the OEKO-TEX®.

MISION

Since its beginnings, RMT has always been linked to the textile world and specifically to wool (reclamation & sheared) along with its many related processes. Along its history and while developing these processes, RMT has been environmentally conscious, since wool scouring has a significant environmental impact due to its water consumption and pollutant load.

In 1992, it outsourced its scouring processes, and has since created new environment-friendly treatment processes through innovation, such as dry bleaching. This process has assisted in the discovery of new applications and treatments to be applied to textile fibres, which are used on the new RMT-NITA product line, now part of RMT INSULATION.